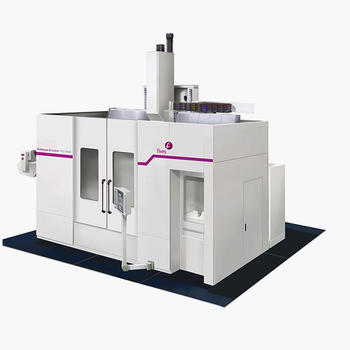

VTC - 1.25 to 3.5 meter tables

Fives’ 1.25 to 3.5 m Giddings & Lewis adjustable rail vertical turning centers have standard features and options that make them the industry standard for vertical turning. The latest innovation added is a Y-axis attachment capable of machining off-centerline part features.

VTC advantages

The adjustable rail elevation which uses precision linear scales has an infinite number of cross slide positions and accommodates a wide range of parts.

Full X-axis travel, left and right of center, allows cutting from both sides of center and probing part diameters optimizing turning operations.

Hydrostatic ram adds stiffness for heavy cuts, better surface finishes and greater accuracy.

Productive options include live spindles, side heads, grinding attachments, pallet shuttles and more.

Specifications

| Machine specifications | VTC 1000 - 3500 |

| Table size (mm) | 1000 – 3500 |

| Maximum swing (mm) | 1300 – 3700 |

| Table speed (rpm) | 630 – 130 |

| Ram head | |

| Ram size (mm) | 250 x 250 |

| Z-axis vertical travel (mm) | 750 – 1250 |

| Rapid traverse (m/min) | 20 |

| Table | |

| AC drive motor (kW) | 75 – 108 |

| Maximum torque (Nm) | 17,113 - 77,164 |

| Thrust bearing load capacity (kg) | 82,200 - 113,400 |

| Tool magazine | 26 - 200 positions |

Applications and operations

The versatility of Giddings & Lewis vertical lathes is unmatched. Plunge milling, helical interpolation, high feed milling, grinding and hard turning are just a few of the advanced processes. Our application experts can help you determine the operations best suited for your parts. See some of the action for yourself in our videos.

- Add machining-center capabilities and machine in one setup with live spindles.

- Drill, mill and tap the sides of a part with a right angle head live spindle.

- Four axis machining, with two heads, allows simultaneous cutting. Perform OD and ID cuts at the same time. Rough with one head and finish with the other.

- Cut from both sides of center and probe diameters with full X-axis travel, left and right of center.

- Available on 1.25 to 3.5 m VTCs, the side head option is ideal for pinch turning or machining of tall or flanged parts.

- For higher volume jobs, the automation of a pallet shuttle optimizes production time. Operators may setup parts while the machine is cutting.

Available options include

- Y-axis attachment

- Live spindles

- Right angle head live spindles

- Grinding attachments

- 4-axis models with two rams

- Pallet shuttles

- Tool and part probes