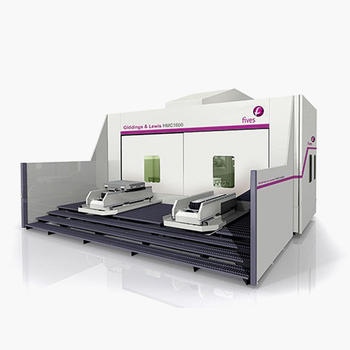

Four and five axis horizontal machining centers

Designed with extensive Six Sigma “Voice of the Customer” input, the HMC 1250 and HMC 1600 meet the needs of today’s manufacturers with speed, rigidity, capacity and versatility.

HMC Series advantages

- High performance drive and way system provides both superior stiffness and allows fast traverse, 35 to 40 m/min.

- Large capacity with 2400 and 3000 mm work zone swing.

- Productive standard features include: linear scales, high-pressure coolant through the spindle and 4th axis contouring rotary tables.

Specifications

| Machine specifications | HMC 1250 | HMC 1600 |

| X-axis travel (mm) | 2100 | 2700 |

| Optional X-axis travel (mm) | 2700 | 3300 |

| Y-axis travel (mm) | 1500 | 1800 |

| Optional Y-axis travel (mm) | 1800 | 2100 |

| Maximum work zone swing (mm) | 2400 | 3000 |

| Maximum work zone height (mm) | 1750 | 2050 |

| Feeds / rapid traverse (m/min) | 40 | 35 |

| Pallet size (mm) | 1250 x 1250 | 1250 x 1600 |

| Optional pallets (mm) | 1600 x 1600 | |

| 1600 x 2000 | ||

| Allowable load (kg) | 5,000 | 7,000 |

| Optional load capacity (kg) | 15,000* | |

| Number of positions | 360 | 360 |

| * Optional load capacity available on 1600 x 2000 mm pallet only | ||

Applications and operations

The rigidity of Giddings & Lewis horizontal machining centers makes it possible to take heavy cuts.

Giddings & Lewis HMCs offer a live spindle option.

High torque spindles combined with the machine rigidity easily machines hard metals such as titanium and Inconel.

View the application report to see how a job shop improved part quality with the precision of the Giddings & Lewis HMC Series.

Available options:

Several headstocks available including: live spindle, tilt spindle, high torque and high speed.

Travels.

Contouring heads and programmable boring bars (available on live spindle models only).

Large capacity tool magazines.

Tool and part probes.

Controls – Siemens or Fanuc.

Coolant systems.

Multiple pallet systems.